Make Certain Optimum Efficiency: Picking the Right Komatsu Undercarriage Parts for Your Fleet

Wiki Article

Efficient Solutions: Undercarriage Components for Heavy Equipment

When it comes to hefty machinery, the undercarriage is an important element that often figures out the overall performance and efficiency of the devices. Quality undercarriage parts play a considerable duty in making certain the smooth operation and longevity of hefty machinery. From excavators to dozers, each piece of devices relies greatly on its undercarriage to stand up to difficult working problems. Wear and tear are inescapable, leading to potential problems that can hinder efficiency and boost upkeep expenses. In this conversation, we will discover the value of investing in excellent undercarriage parts, usual wear challenges encountered by heavy machinery operators, the advantages of timely substitutes, guidelines for selecting reputable vendors, and important upkeep tips to prolong the lifespan of undercarriage elements.Importance of High Quality Undercarriage Parts

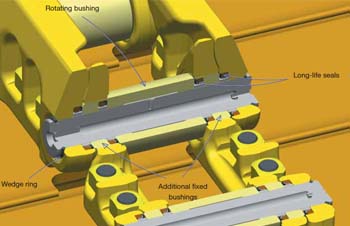

Quality undercarriage parts are necessary parts in making certain the sturdiness and efficiency of hefty equipment. The undercarriage of devices such as excavators, excavators, and track loaders plays a crucial function in supporting the maker's weight, supplying security on different surfaces, and absorbing the impact of uneven surfaces. By purchasing high-quality undercarriage components, operators can substantially prolong the life expectancy of their machinery and decrease the risk of unforeseen malfunctions.One secret benefit of using quality undercarriage components is the enhancement of overall machine efficiency. Sturdy tracks, rollers, sprockets, and idlers reduce rubbing and make sure smoother motion, inevitably bring about boosted efficiency and efficiency on work sites. Furthermore, reputable undercarriage components minimize downtime for upkeep and repair work, allowing operators to maximize their functional hours and project target dates.

Usual Undercarriage Use Issues

Advantages of Timely Replacement

One secret benefit of timely undercarriage part substitute is raised equipment uptime. By changing used components prior to they stop working, the risk of see unexpected breakdowns is decreased, decreasing downtime for repair work and maintenance. This aggressive strategy not just keeps the heavy equipment operational yet likewise avoids potential damages to various other components that might result from a failing undercarriage.

Additionally, changing undercarriage parts promptly can boost total productivity. Spending in prompt undercarriage component substitute is an aggressive technique that pays off in terms of boosted efficiency and reduced operational prices.

Picking the Right Undercarriage Supplier

Choosing the appropriate undercarriage vendor is an essential decision that dramatically affects the performance and maintenance of hefty equipment. When picking a vendor for undercarriage parts, a number of aspects have to be considered to make certain optimum efficiency and cost-effectiveness. A distributor that supplies a broad option of undercarriage parts for various heavy equipment brands and models can be helpful as it offers more options to fulfill details needs.Moreover, reviewing the provider's consumer solution and support is vital. A distributor that offers superb client service, quick response times, and technical help her explanation can assist minimize downtime and guarantee smooth procedures. Price is additionally a substantial factor to take into consideration; nonetheless, it ought to not be the single component. When choosing the right undercarriage vendor for heavy equipment, stabilizing cost-effectiveness, dependability, and quality is essential. By meticulously reviewing these factors, you can select a vendor that satisfies your needs and contributes to the efficient performance and maintenance of your heavy equipment.

Upkeep Tips for Extended Lifespan

To make certain an extended lifespan for hefty machinery undercarriage parts, applying an aggressive maintenance regimen is important. Regularly checking undercarriage components such as track chains, idlers, rollers, and sprockets for damage is critical. Any indications of damage or extreme wear should be promptly dealt with to avoid more official statement wear and tear and potential failings. Additionally, maintaining the undercarriage clean from dust, debris, and destructive materials can dramatically extend its life-span. Greasing relocating parts according to maker referrals helps in reducing friction and stop premature wear. Checking track tension and positioning is additionally essential to stop uneven wear on the undercarriage elements. Spending in quality undercarriage components from reliable suppliers is just as important for making sure long life. By following these maintenance ideas faithfully, heavy equipment proprietors can maximize the performance and sturdiness of their undercarriage components, inevitably reducing downtime and operational expenses.Final Thought

Finally, high quality undercarriage components are necessary for the efficient procedure of hefty equipment. Prompt substitute of used parts can avoid expensive downtime and preserve ideal performance. Selecting a reliable supplier and complying with correct maintenance techniques are vital to making certain the expanded life-span of undercarriage components. By addressing usual wear problems and spending in top notch components, heavy equipment operators can take full advantage of productivity and lessen upkeep expenses.

Extreme wear and tear on undercarriage parts of heavy equipment can lead to substantial operational challenges and increased upkeep prices. Routine evaluations, proper upkeep, and timely replacements of used undercarriage components are important to mitigate these usual wear issues and guarantee the optimal performance of heavy machinery.

A distributor that offers a broad selection of undercarriage components for different heavy equipment brands and versions can be helpful as it provides more alternatives to meet details requirements.

By following these upkeep suggestions faithfully, heavy equipment owners can maximize the performance and durability of their undercarriage components, ultimately decreasing downtime and functional expenses.

Report this wiki page